Control Center Engineering Software

Best in industry Product width

Manufacturing – Design – Assembly – We have a complete and integrated solution

The Consumerization of electronics has been the driving force for innovation in both semiconductor and system OEM companies to address the demand for functionality convergence. As a result, electronics products today include combinations of complex low-power, low-cost packages and miniature, high-speed printed circuit boards.

This presents tremendous challenges for electronics teams tasked with developing and delivering these products to market.

Our solutions teams with everything they need to get their jobs done effectively— from integrated flows to engineering chain management to services—all of which combined reduce quality and functionality risks while improving predictability. In addition, Direct Logix offers engineering design services to help customers meet their broader business and project goals

Control Center Server

▣ CCS 1000 ▣

the Control Center Solution core module for plugin modules available below

Putting it all together, the Control Center Server provides web pages of the content that you desire, and also provides in-browser as well as email notifications for end users and administrators.

Requires Server hardware

↓ Available module options below ↓

Automatic Traveler Generator

– ATG 1000 –

Use this product to generate a rules-driven manufacturing work instructions set (i.e. Lot Card/Traveler/Batchcard). View the instructions electronically or print them as hard copies. Fully integrated with your ERP system, the operations list is transferred to the site manufacturing system. Product attributes, specific notes, standard instructions and graphic attachments form an integral part of the instructions. Easily imported into leading shop floor control systems.

Prerequisites EDM, DPB

Typical training days 3

Design Data Manager

– DDM 1000 –

The integrated solution for storage, retrieval and ITAR data control. A multi user document repository (knowledgebase) , document manager and/or document management system (DMS) for publishing of files/documents onto the web for a corporation, single factory, group of people, or just for yourself. A document can be any type of electronic document or file that the user can access from their computer. Once documents have been captured by the system users have numerous options. All these facilities are easily available through the use of an Internet Browser.

Prerequisites EDM

Typical training days 2

DF(X) Communicator

– DFX 1000 –

Software package enables graphical review of all stored production DFM attributes, without accessing the graphics environment. Allows for the creation of graphical PCB Fabrication, PCA assembly, and mechanical DF(x) report with action items, owner, status, cost and threaded discussions. Supports a variety of PCB Layout and other systems.

Prerequisites EDM and IRM

Typical training days 2

Dynamic Page Builder

– DPM 1000 –

Allows users to develop and deploy custom web pages to the factory floor with access to full engineering knowledge base. Allows for the combination of fields from internal as well as external databases. Provides the systems engineer with a incredibly powerful automation tool to build custom in house applications. Full support for custom javascript widgets such as calculators, etc…

Prerequisites CCS

Typical training days 1

Design Release Manager

– DRM 1000 –

Provides the mechanisms to create an external users in the system, login, segregated user data, define job matrix set up information. This allows for the automation of the delivery of DF(x) reports. Utilizing a DFM engine, the system provides the most advanced automatic algorithms in the industry to allow for the “drop off” over the web or internally of customer design packages. The algorithms in minutes prepare data and users receive back via email comprehensive DFM reports. Internal CAM personnel receive clean single image PCB data for processing. This module generates large productivity improvements.

Prerequisites, EDM, EPM, DFX and IRM.

Typical training days 1.

ECO/MCN Director

– ECO 1000 –

Extending the power of the Control Center database with Engineering Change Orders and Manufacturing Change Notices has never been easier. Track and assign notices with ease now. Integrated with user management and the messaging framework.

Prerequisites EDM

Typical training days 2

Engineering Design Manager

– EDM 1000 –

Repeatable automation, job status, statistical reporting of time elements by technology, individual, step, group and more. Clear color coded view to project status, engineer(s), location of activity, due date and more.

Typical training days 1

Engineering Procedure Manager

– EPM 1000 –

Consistent automation, job status and engineering routing control. Allows for the administration of Users, States, Processes, Groups and Routes for Engineering. This advanced automation framework allows for complete procedure control of the entire engineering process. The open nature of the system allows for simple an easy support of automation from many cam, impedance and other software suppliers. Provides full traceability, tracking and training features.

Prerequisites CCS

Typical training days 1

Immediate Response Module

– IRM 1000 –

Detailed DFM reports summarized in a simple web page and interface. The Immediate Response module further leverages OSM and MCM 1000 modules to display DF(x) analysis color coded. “What if Analysis” is possible to obtain DFM results within seconds.

Prerequisites EDM

Typical training days 1

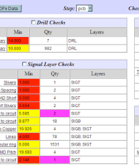

Manufacturing Capabilities Manager

– MCM 1000 –

Manages supplier specs electronically with back tracing, revision control and fall through logic. Compare a job to one or more specs and receive color-coded comparison results. Discover the cause of discrepancies and generate corrective-tooling instructions accordingly. Spec content is user configurable and spec quantity unlimited. In addition to customer and manufacturing specs, new spec types may be added to suite operational needs.

Typical training days 1

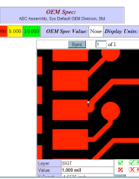

OEM Specification Manager

– OSM 1000 –

Manages customer specs electronically with back tracing and revision control. Compare a job to one or more specs and receive color-coded comparison results. Discover the cause of discrepancies and generate corrective-tooling instructions accordingly. Spec content is user configurable and spec quantity unlimited. In addition to customer and manufacturing specs, new spec types may be added to suite operational needs.

Typical training days 1

Panel Layout Designer

– PLD 1000 –

The PLD application provides the next generation in advanced web based panel layout. Having for the first time a true shape based algorithm to define panel layouts with many constraints then select the final layout for direct output to the legacy step and repeat CAM system.

Prerequisites EDM

Typical training days 2

Quotation Builder

– QBM 1000 –

Use this product to generate a rules-driven manufacturing work instructions set (i.e. Lot Card/Traveler/Batchcard). View the instructions electronically or print them as hard copies. Fully integrated with your ERP system, the operations list is transferred to the site manufacturing system. Product attributes, specific notes, standard instructions and graphic attachments form an integral part of the instructions. Easily imported into leading shop floor control systems.

Prerequisites EDM, DPB

Typical training days 3

Stackup Builder

– SBM 1000 –

As with most other modules of the Control Center suite the SBM 1000 takes web enabled engineering applications to the next level. For over 10 years, Direct Logix has provided web based application to the PCB fabrication industry. Being the leader we now offer the first iPad/tablet application for PCB stackup definition, impedance calculations and much more. Imagine the sales, marketing and internal operations benefits to using a light weight accessible anywhere application. Wether its in the conferences room, with the customer or on the trade-show floor you now can have access to your own material library, your own impedance calculation methods all with the simplicity of the Direct Logix Control center server suite.

Prerequisites EDM

Typical training days 2

MultiWorx

– MWORX i-

The most advanced methodology available to predict registration and more importantly feedback predictions into engineering. Only the Control Center system offers a single integrated solution for full predictive engineering combining Xray hardware, historical review and pre production engineering prediction. Incredible ROI and ultra fast payback period is common.

Typical training days 2

Third party software and hardware required